Examination of shafts with cracks

1. Order Description

Cracks were found on forged shafts after induction hardening. Through a fractographic SEM – examination of the cracks and a metallographic comparison of n. i. O – Share with i. O – parts, the cause of the crack should be determined.

2.1. REM – examination

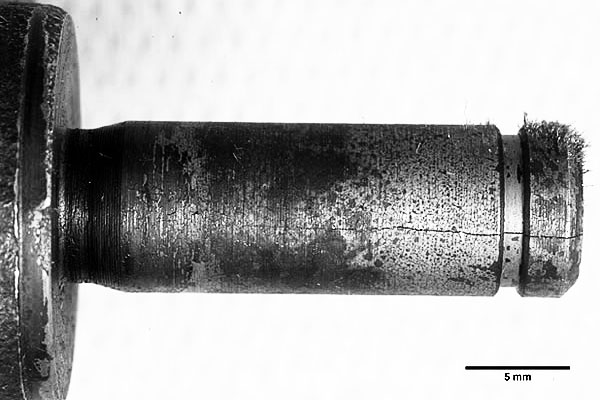

The location and extent of the cracks, both axially and radially, are documented in the macro image.

- Makroaufnahmen der gerissenen Welle

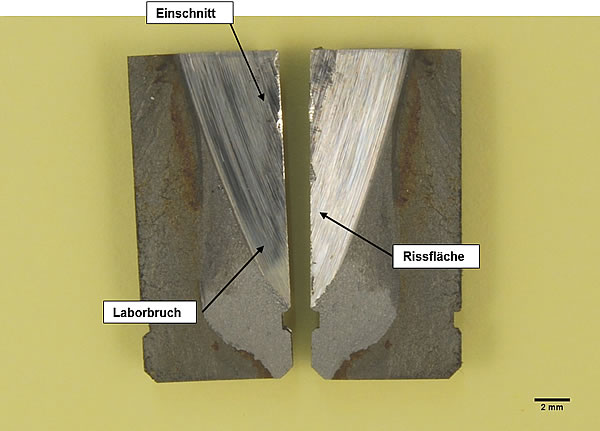

- Makroaufnahme beider Hälften des aufgebrochenen Risses

The tear was broken open after cutting the sample from the back. The color of the crack surface can be clearly distinguished from the fracture surface of the forced laboratory fracture. The surface of the crack is covered with a quenching agent, which partially spread to the laboratory fracture surface after the cracking, recognizable by the partial discoloration of the laboratory fracture surface.

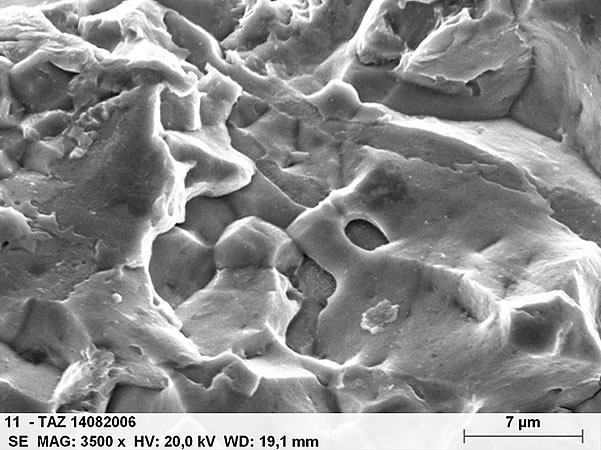

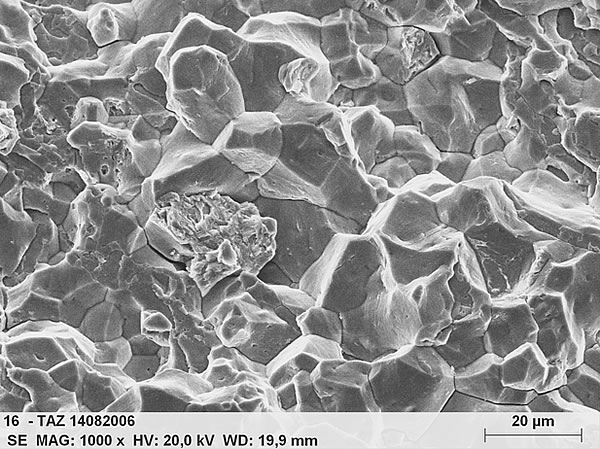

The crack runs intercrystalline, with the grain boundaries sometimes not running smoothly, but rather showing a “rounded” appearance, which suggests a temperature influence near the melting point range, i.e. a hot crack. Since the grains do not have a dendritic structure and impurities or precipitations can be seen on the grain interfaces, it is likely a remelting crack.

- Interkristalliner Bruch auf der Rissbruchfläche

- z. T. „eingerundete“ Körner

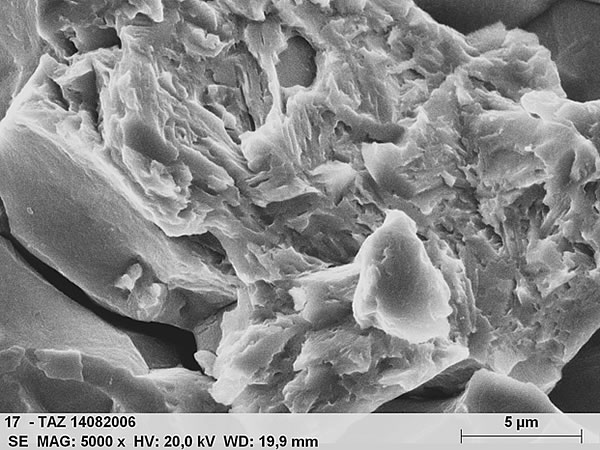

- Rissbruchfläche – andere Stelle mit Schmelzstrukur

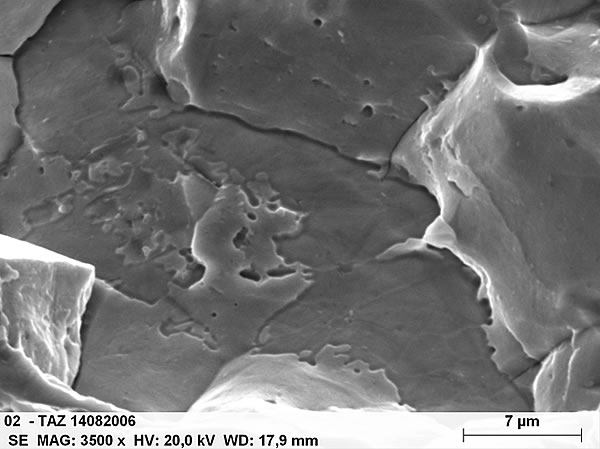

Like the crack, the forced laboratory fracture also shows an intergranular cleavage fracture. Individual grains are broken and show microfission surfaces. This smooth intergranular fracture with z. T. expanded grain boundaries and the proportion of transcrystalline fracture with microcleavage surfaces indicates the possibility of hydrogen embrittlement.

- andere Stelle – transkristalline Bruchanteile und aufgeweitete Korngrenzen

- Korn mit transkristallinem Bruch mit Mikrospaltflächen

2.2. metallography

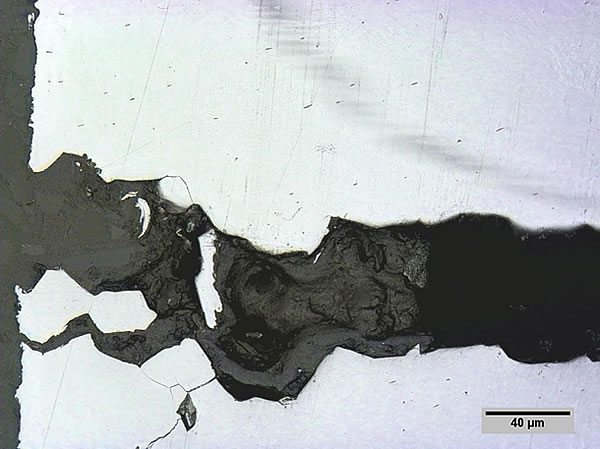

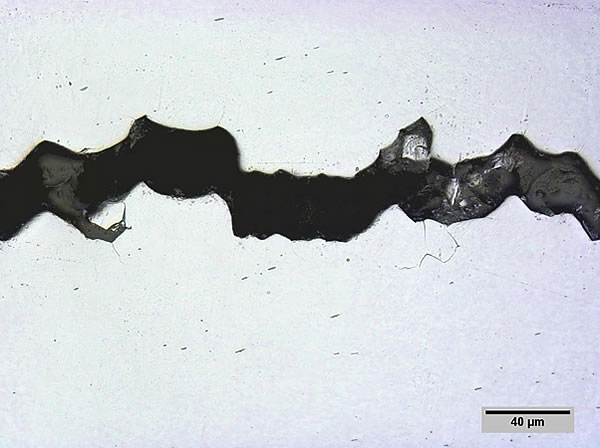

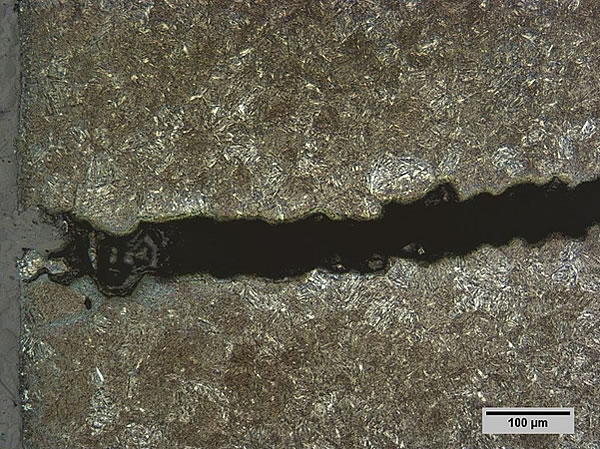

The cross-section of sample 3 n.i. O. confirms the course of the intergranular cracks determined during the REM examination. The partially rounded grain boundaries are also clearly visible.

- Rissbeginn

- Mitte Riss – Rissflanken bzw. Korngrenzen z. T. eingerundet

- Rissverlauf Rand, Vergütungsgefüge, geätzt mit Nital

The structure in the crack area, tempered structure, does not differ from the surrounding structure.

Summary and assessment

Cracks in forged and hardened shafts were examined using SEM/EDX and metallography.

The crack surface shows an intergranular fracture whose grains z. T. have a “rounded” appearance. This structure does not indicate a typical hardening crack, but rather a hot crack, more precisely a so-called remelting crack, which can occur if the temperature is imprecisely controlled during hot forming.

It is striking that the forced laboratory fracture that occurred when the crack opened also shows an intergranular fracture. This fracture with smooth grain boundaries with partially expanded grain boundaries and proportions of transcrystalline cleavage fracture with so-called micro-cleavage surfaces gives an indication of any hydrogen embrittlement that may be present.

The metallographic examination shows no difference between the n.i. O. sample and the i. O.—Sample. Both samples show a tempering structure. Both samples are fully hardened.

Thomas Asam

(Managing Director)

Eurasburg, 01.09.2014