Nano indenter for instrumented penetrant testing

| Model: | Fischer Picodentor HM500 |

| Test force range: | 0,005 – 500 mN |

| Force resolution: | ≤ 100 nN |

| Path resolution: | ≤ 40 pm |

| Damping system: | Active damping table |

| Measurable hardness: | 0,001 – 120.000 N/mm2 (near diamond hardness) |

| Design: | Vickers |

A Vickers test diamond is used as the test specimen. Due to the very small penetration depths, the test can be considered to be virtually non-destructive.

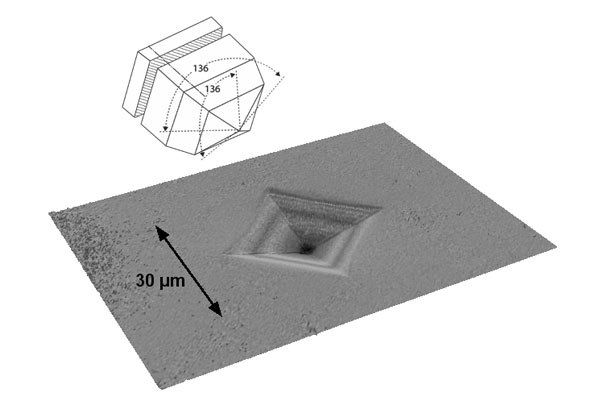

Hardness impression with Vickers test diamond

(Recording Keyence LSM VK9710)

With the nano indenter, the hardness and other material parameters are determined with very small test forces. Thus, for example, coatings and structural components can be examined.

Nanoindentation (or nanoindentation) is carried out as an instrumented indentation test according to DIN EN ISO 14577. In contrast to conventional hardness testing methods, not only the plastic behavior of the material is determined. In addition to the Martens hardness and the indentation hardness (including conversion to Vickers), other material parameters can also be determined from the resulting force-indentation depth curve.

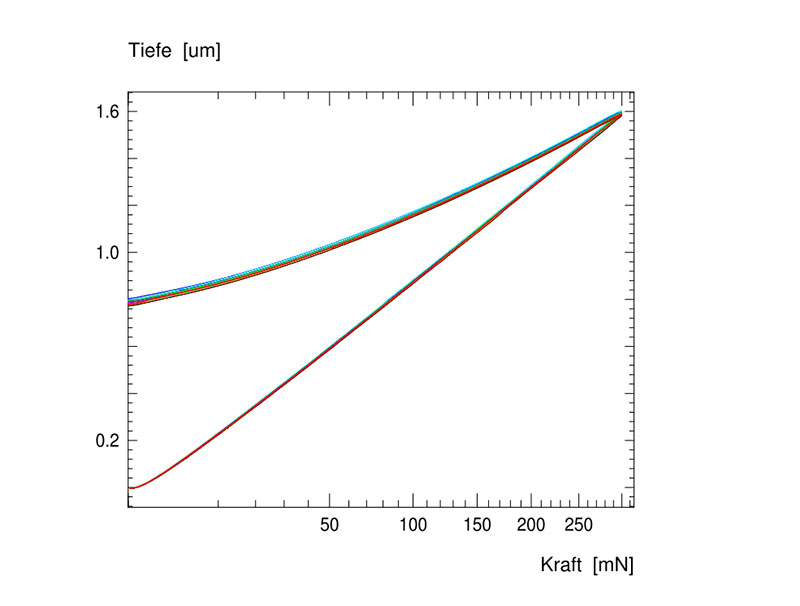

Force penetration depth curves (borosilicate glass BK7)

- Material properties calculated according to DIN EN ISO 14577:

- Martens hardness HM

- Indentation hardness HIT (can be converted to Vickers HV)

- Ingress Module EIT

- indentation creep CIT

- Percent elastic part ŋIT of the indentation work Welast/Wtotal

- Martens hardness at a specific test load

- Fraction of plastic deformation

- ESP mode, partial load and discharge measurements to determine quantities such as EIT and HIT depending on depth or load

With nano-indentation, the test force and the indentation depth are continuously measured during the loading and unloading process. Therefore, nanoindentation is also referred to as instrumented penetrant testing. Material characteristics near the surface are determined from the resulting force-penetration depth curve. The special ESP mode (enhanced stiffness procedure), in which the test force is varied cyclically, enables a quick force- and depth-dependent determination of parameters such as the elastic indentation modulus (EIT), the indentation hardness (HIT) or the Vickers hardness (HV) at a sample location.